Code of Practice Four

Code of Practice Four |

Guidance Note |

Code of Practice 4

Commissioning

What is Half Hourly Commissioning?

Who is responsible for Commissioning?

This guidance relates to Issue 6 of Code of Practice 4 |

What does the Commissioning organisation do?

Who is responsible for safety?

Scope of the Commissioning Tests

The current transformers are of the correct ratio, phase and polarity;

The current transformers are correctly located to record the required power flow;

The voltage transformers are the correct ratio and phase;

The voltage transformers are correctly located to record the required voltage;

The burdens on the measurement transformers are within the correct limits;

The Meters are set to the same current transformer and voltage transformer ratios as the installed measurement transformers;

The Meters have the correct Compensation (e.g. for errors in the measurement transformers/connections and losses in power transformers1 ), where appropriate;

The Metering System correctly records the energy at the Defined Metering Point;

Phase rotation is standard at the Meter;

The operation of the test terminal block; and

Half Hourly Metering Equipment detects phase failure and operates the required alarms.

I’m the Commissioning organisation. What should I do?

Inspection/Tests

Check the Metering System is complete and that it won’t be changed after the Commissioning tests are performed.

Record nameplate details from the measurement transformers, Meters, Outstations (where separate from the Meter) and metering protection equipment.

Check that measurement transformers and Meters have Calibration Certificates for the correct Class and that the serial numbers match. Check that Meter Compensation information is included with the Meter Calibration Certificate.

Check any auxiliary supplies to the Metering Equipment are available and are the correct voltage.

Check the settings to any metering protection equipment and ensure discrimination between protection equipment, i.e. lowest rating nearest the Meter/Metering Equipment.

Confirm the correct operation of the local interrogation facility (Meter or Outstation).

Check the external communications to the Meter/Outstation are functioning and are in accordance with the Meter Technical Details (MTDs) (where required2 ).

Installation Data

Proving Measurement Transformer Ratios

Current Transformers

Inject each primary current transformer in turn and check that secondary current is passing through the Meter and the test terminal block(s).

Record the primary and secondary currents.

Check the current transformer ratio against the Meter Technical Details.

Carry out direct current flick tests to establish polarity.

Voltage Transformers

For polyphase3 voltage transformers, inject two or three phase voltages onto the primary of the voltage transformer (400V or 230V is usually adequate).

Record primary and secondary voltages and phase rotation at the Meter and the test terminal block(s).

Where voltage transformer neutral connections are available, inject single phase from each primary phase to neutral and record the secondary phase to neutral voltages.

Then calculate, record and check the voltage transformer ratio against the Meter Technical Details.

Burden Tests

Inject current as close as is practical to the measurement transformers to establish and record the burden on the current transformers and voltage transformers.

Where primary injection has not been performed check that current and voltage is present at the Meter and the test terminal block(s).

Check that the burden ratings are within the normal operating range of the measurement transformers.

Where burden values are used to compensate the Meter, check that any estimated values are accurate.

Record the value of burdens (including any non-Settlement burdens) necessary to provide evidence of the overall metering accuracy.

Secondary Injection Tests

Inject current and voltage from the test terminal block(s) into the Meter at the rated values.

Check that the injected energy matches all the outputs of the Meter, which may (when fitted) include test Light Emitting Diodes (LEDs), dials, pulse outputs and communication port data.

Where there are separate Outstations installed, check that energy injected is correctly recorded by the Outstation.

Phase Failure Detection Tests

For CVA, inject any installed metering protection equipment, e.g. voltage transformer phase failure or phase unbalance equipment. Check for correct settings and monitor the local and remote alarms.

For SVA, carry out tests to confirm the correct operation of Meter voltage failure indicators.

Commissioning Tests with the System Live

Carry out a prevailing load check by measuring the energy at the test terminals against the recorded energy at the Meter. Confirm that the main and check Meters are recording identical values of energy.

Verify the phase sequence of the metering voltage transformer secondary connections against another known voltage transformer connected to the same source. Confirm the ratio of the voltage transformer by comparison.

Measure the metering current transformer secondary current and compare with the secondary current from an independent current transformer, which has its primary connected in series with the metering current transformer. You can use a current clamp meter for this test. This test is used to confirm that the correct current transformer tap was selected. These values should be within 10% of each other.

For both CVA and SVA

Carry out a phase rotation test at the test terminal block(s) and the Meter. The Meter must be standard phase rotation.

Where possible, confirm that the Meter is recording similar current and voltage values to primary or secondary load.

Carry out a test to confirm the operation of the test terminal block(s).

At the end of all the tests you should record enough information to demonstrate that the Overall Accuracy of the Metering System is within the limits of the relevant Code of Practice. |

Records

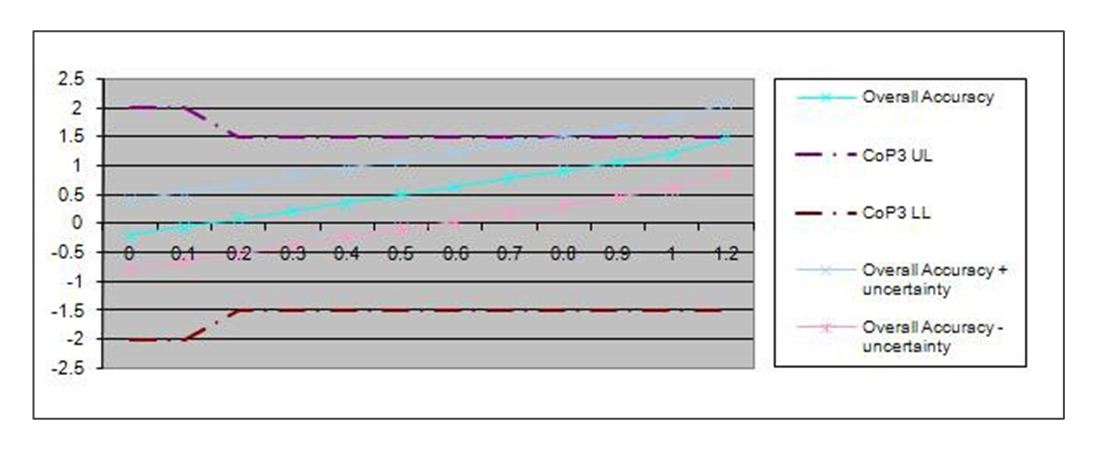

Measurement Uncertainty

What is Measurement Uncertainty?

What do we mean by repeatability?

How to limit influencing factors

Overall Accuracy

What is Overall Accuracy?

The measurement errors associated with the individual items of Metering Equipment that make up the Metering System (including the measurement uncertainty associated with the measured values obtained through their Calibration);

Any measurement error contributions due to the connections between each item of Metering Equipment (e.g. leads connecting measurement transformers to the Meter); and

Compensation that has been deliberately added to the Meter to account for:

any measurement error due to the AMP not being at the DMP (i.e. for Power Transformer and Line Losses); and/or

measurement errors associated with measurement transformers (see section 4.3.2 ‘Compensation for Measurement Transformer Error’ of CoPs 1, 2, 3 and 5).

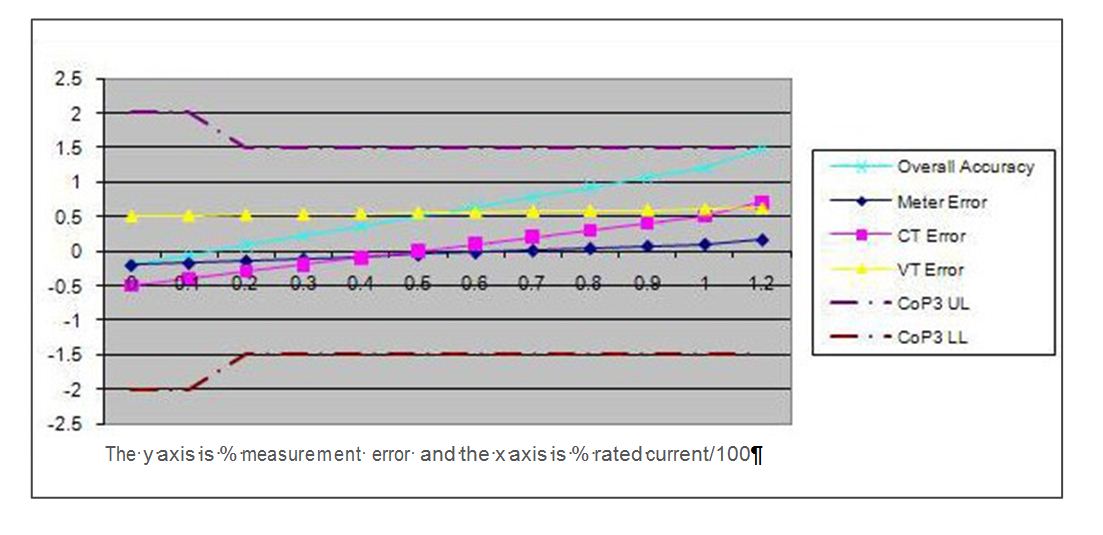

What happens when Compensation isn’t applied to a Meter?

the Meter;

the current transformers (CT); and

the voltage transformers (VT).

Replace an item or items of Metering Equipment with a better (higher) accuracy class; or

Calibrate an item or items using Calibration equipment with a better (lower value) measurement uncertainty statement; or

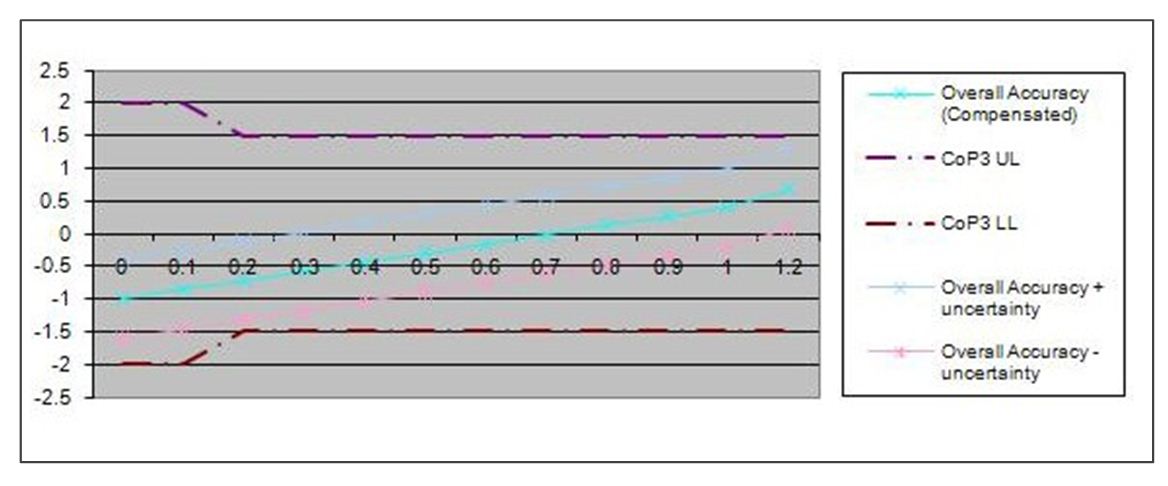

Compensate the Meter to bring the Overall Accuracy curves within the UL and LL of CoP3.

What happens when Compensation is applied to a Meter?

CT error at actual burden (which may change with loading);

VT error at actual burden (which may change with loading);

Any influences due to non-Settlement burdens (and any changes to these burdens);

Voltage drop in leads (and associated circuitry) connecting measurement transformers; and

Power transformer iron and copper losses (which vary with loading).

Need more information?

Intellectual Property Rights, Copyright and Disclaimer The copyright and other intellectual property rights in this document are vested in Elexon or appear with the consent of the copyright owner. These materials are made available for you for the purposes of your participation in the electricity industry. If you have an interest in the electricity industry, you may view, download, copy, distribute, modify, transmit, publish, sell or create derivative works (in whatever format) from this document or in other cases use for personal academic or other non-commercial purposes. All copyright and other proprietary notices contained in the document must be retained on any copy you make. All other rights of the copyright owner not expressly dealt with above are reserved. No representation, warranty or guarantee is made that the information in this document is accurate or complete. While care is taken in the collection and provision of this information, Elexon Limited shall not be liable for any errors, omissions, misstatements or mistakes in any information or damages resulting from the use of this information or action taken in reliance on it. |

1 Where the measurement transformers are not at the Defined Metering Point then a Metering Dispensation is required (see BSCP32: Metering Dispensations).

2 Where no Communications Equipment is fitted the Data Collector will take Meter readings locally, using a hand held unit.

3 Guidance on testing single phase voltage transformers will be added as it becomes available.

4 Primary source should be a direct source where possible using a current clamp ammeter and voltmeter. You could use an independent current transformer which has its primary connection in series with the metering current transformer or independent energy meters, voltage and current meters.

5 The Compensation applied should reflect the electrical losses between the DMP and the AMP. In some cases, the difference may be negligible but the Compensation will still be the subject of a Metering Dispensation.

6 Under CoP4, measurement uncertainty needs to be determined to a confidence level of 95% or greater. Assuming a normal Gaussian distribution applies, then a coverage factor (k) of 2 will give a 95.45% confidence level (or coverage probability). Read the UKAS document, M3003 ‘The Expression of Uncertainty and Confidence in Measurement’ for more information.

7 Modern static Meters present low burdens to measurement transformers and so you should consider whether the operating burden on the measurement transformers are within their operating ranges. In such cases it may be necessary to add additional burden and as a consequence the individual error contributions may change.